Finding the perfect configuration

for your available space

Module Configuration

Blue Foot has developed standardized, modular and above all stackable membrane modules to allow customers to standardize their solutions for end-users.

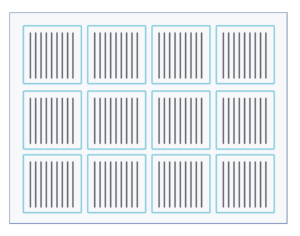

MULTIPLE SHEETS, ONE MODULE

To function in a process, multiple membrane sheets are combined into a single membrane module, the smallest unit in any membrane bioreactor. One Blue Foot membrane module consists of many evenly distributed membrane sheets side by side. The spacing of the individual membrane sheets is critical, ensuring an equal flow of sludge and air along all membrane sheets.

multiple modules, one stack

To obtain minimal footprint and minimal energy consumption for air scouring, up to three modules can be stacked. The stacks are easy to assemble, install and maintain. They are fully standardised and allow for a modular build-up of any membrane bioreactor plant. Since all modules in a stack use the same air diffuser box, both aeration and footprint are minimised.

Multiple stacks, many possibilities

Stacks offer a versatile and adaptable solution that can be tailored to meet the specific needs of any plant. As the plant grows and the demand increases, additional stacks can be added to the existing configuration, allowing for greater capacity and flexibility. To optimise efficiency, maximise uptime and fulfil all your wastewater treatment plant demands, stacks can be easily grouped to adapt to every situation. This ensures that the plant can continue to meet the demands of the community it serves, both now and in the future.

multiple options, one container

Blue Foot’s modularized approach is also very attractive to apply in mobile, containerized solutions. These offer a convenient, efficient and mobile way to treat water. Specifically for the use of standard high-cube containers, Blue Foot has half-height modules available. The compact, self-contained units can be pre-assembled and ready to use, requiring minimal on-site installation. They can be easily transported to remote or hard-to-reach locations, making them ideal for a range of applications, from desalination to wastewater treatment. With the added benefit of being customizable, containerized solutions provide an effective and reliable solution for those seeking a more flexible and efficient water treatment option.