From product features to customer benefits

performance

The membrane module is often considered the Achilles heel of any Membrane Bioreactor, but Blue Foot has the solution.

A wastewater treatment plant should always be reliable and easy to operate, as business continuity depends upon it. It should also be cost-effective, with appealing OPEX and CAPEX. Blue Foot’s unique membrane technology offers excellent long-term performance and reliability. The membrane sheets’ unique characteristics all result in advantages for our customers. Here’s how.

BACKwashable

THE ONLY FLAT SHEET MEMBRANE THAT YOU CAN TRULY BACKWASH.

Backwashing membranes is very common in non-MBR water treatment applications. However, it is near to impossible in most submerged membrane systems. Especially polymeric flat sheet membranes are prone to immediate damage when backwashed. This makes this short but very effective hydraulic cleaning method useless. This in turn limits the sustainable flux rate, forces non-productive periods for membrane “relaxation” and increases the likeliness of frequent chemical cleaning.

Due to its unique composition, Blue Foot’s Integrated Permeate Channel (IPC®) membrane is designed to be backwashable. The patented 3D structure of each membrane sheet shows the membrane layer integrated into the 3D backing material.

This unique composition is what allows Blue Foot membranes to withstand a backwash pressure of up to 2 bar and provides ample freedom to backwash the membranes under even the most challenging circumstances.

Backwash is a quick and very effective hydraulic cleaning method in a Bioreactor and a required asset for robust operation.

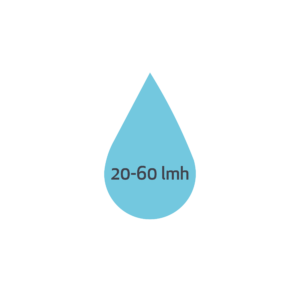

Twice the flux rate compared to competing products

Every membrane is designed to accommodate a certain throughput, known as the flux rate. This is expressed in litres per square meter per hour or ‘lmh’. Typically, flux rates for Membrane Bioreactors are relatively low, ranging from 10-20 lmh, which necessitates installing a large membrane surface area.

The IPC® membrane really sets itself apart from competing products through its very high sustainable flux rate, which is facilitated by the combination of the PVDF membrane material, its true UF morphology with average pore size of 0,04 µm, the membrane sheet design and by the ability to properly backwash these membranes.

The IPC® membrane offers a design flux rate which is approximately double of most competing products in the same application.

Flux

Best PEAKFLOW handling

Flexible in any situation

The distinct advantages described previously enable the IPC® membranes to be much more flexible during peak flow conditions. Not only are the membranes inherently capable of running at higher fluxes, but they also possess the capability to be backwashed, making a speedy recovery from a peak flow condition possible.

The result is a much higher design flux at peak flow conditions of 30-60 lmh depending on the application.

half the energy consumption of most competing systems.

Aeration plays a crucial role in the operation of a Membrane Bioreactor and is responsible for most of the energy consumption. Blue Foot’s high flux, backwashability and compact footprint also result in the lowest aeration rate in the market, typically requiring only half the air of most competing systems.

This results in significantly lower OPEX and a much smaller CO2 footprint.

Due to the reduced aeration requirements, the installation costs for the blower section and piping are significantly lower, reducing your CAPEX.

aeration

footprint

1,5 TO 3 TIMES SMALLER THAN COMPETING SYSTEMS.

The footprint of submerged membrane bioreactors depends on the required flux rate and the module configuration in the basin. The larger the footprint, the larger the tank which is required to house the modules.

Blue Foot’s innovative triple-deck design, featuring compact and stackable membrane modules, offers a large membrane area per square meter of filtration tank footprint. Combine this with our high flux, and the Blue Foot system requires a footprint that is 1.5 to 3 times smaller than that of other systems. Smaller footprint means smaller tanks, less occupation of valuable space and savings on CAPEX.